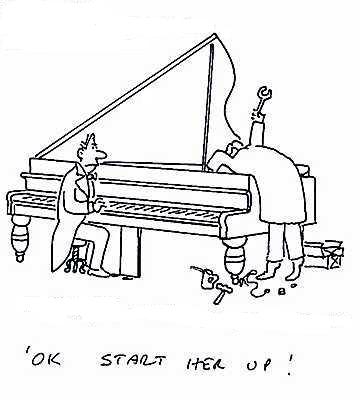

David Renaud, RPT, Piano Technicians Guild

25 years, fine tuning, voicing & rebuilding where quality counts. Trusted by concert halls & musicians throughout the capital region.

cell:

613-288-9046

email: drjazzca@gmail.com

![]()